- Home

- Products

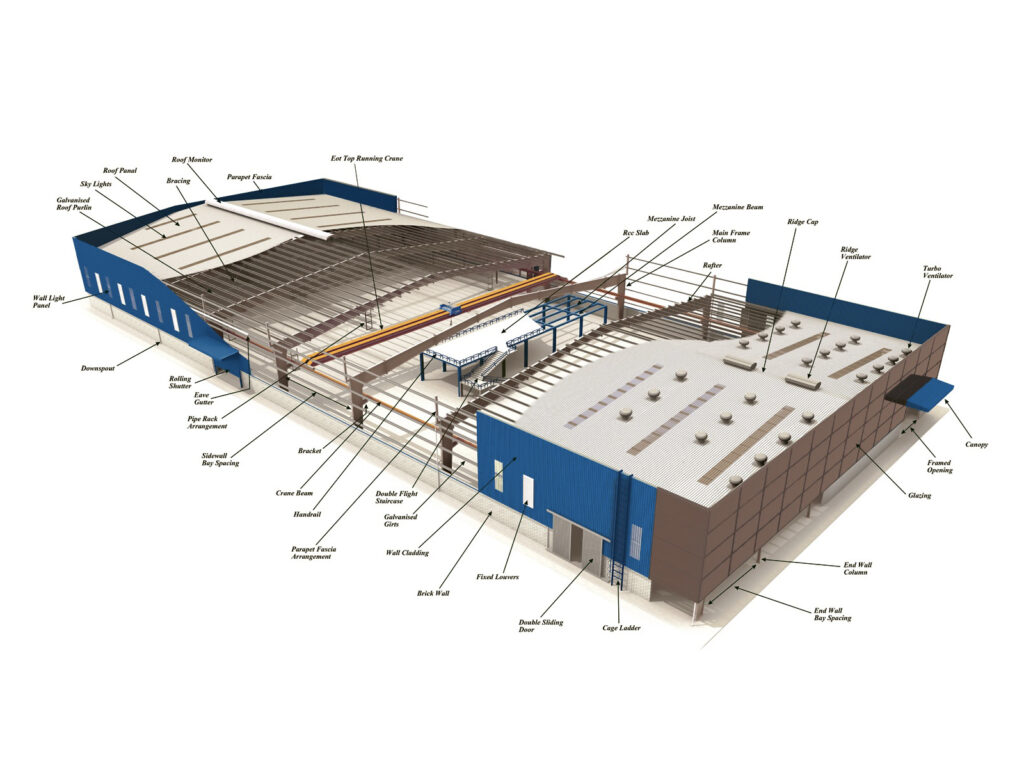

Pre-engineered steel buildings (PEB) are a steel building over a structural concept of primary members (MS Plates built-up members, I beams, MS channels), secondary members (cold rolled profiles), roof and wall sheeting and various other building components. These buildings can be provided with skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascia, canopies, crane systems, insulation etc., based on the customer’s requirements. All the steel buildings are designed to be lighter in weight and high in strength. Steel building designs have become more flexible, durable which has made steel one of the preferred materials for building construction.

Pre-engineered steel buildings has wide range of applications such as factories, warehouses, showrooms, aircraft hangars, metro stations, offices, shopping malls, schools, hospitals, community buildings and many more.

PEB’s are ideal for industrial and wide-span low-rise buildings. Some of the key advantages of PEB include economical in cost, factory controlled quality, durability, longevity, flexibility in expansion, environmentally friendly, faster installation, etc.

We are providing the complete service of engineering, fabrication and erection thus ensuring better quality control at every stage of the process.

Pre-engineered steel buildings consist of following components:

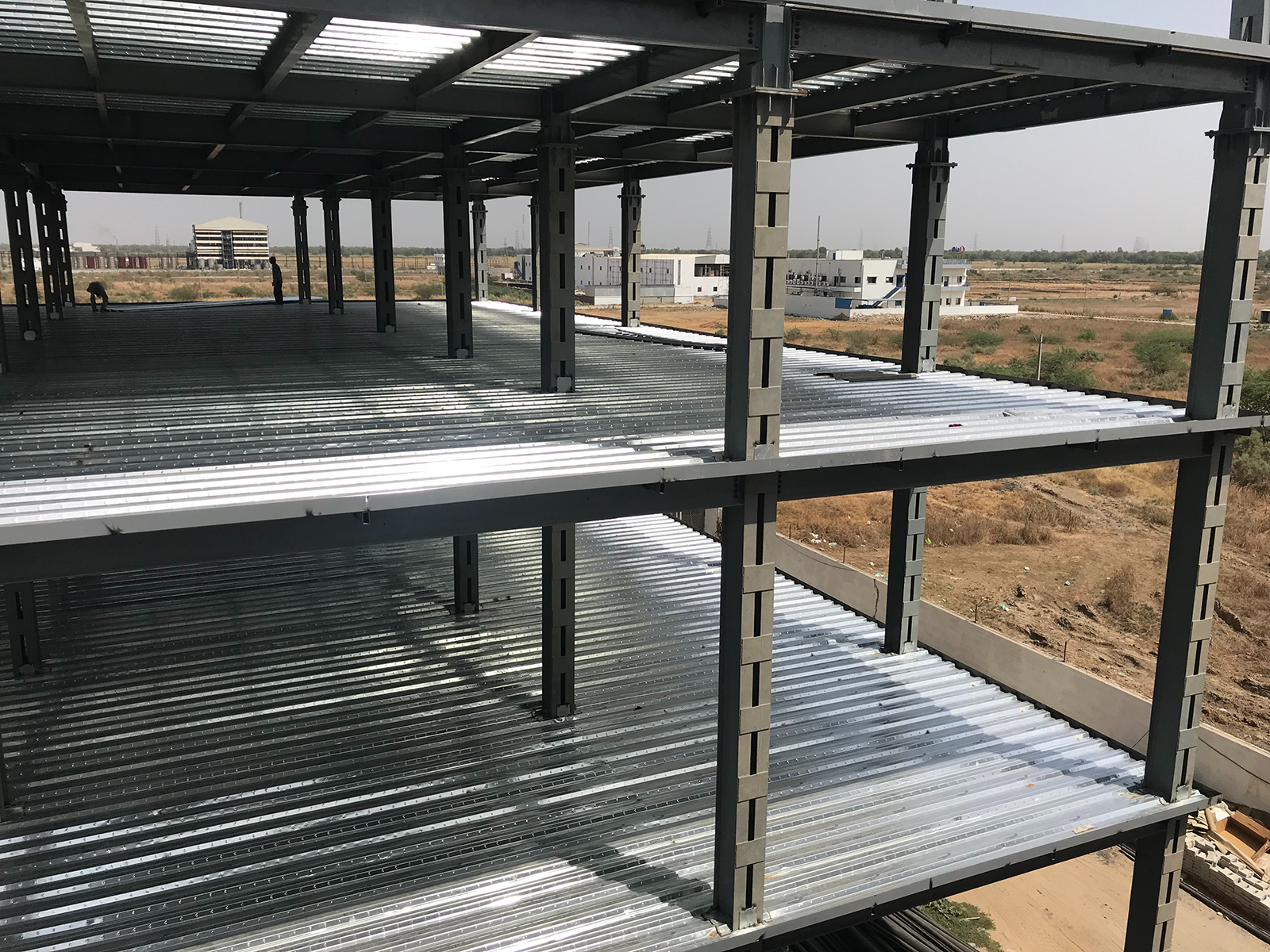

We are involved in providing Multi Storey Steel Buildings as we have large space for production of large quantity of floor beams and columns and supply with well managed erection schedule for faster erection process.

Steel building construction is a very popular structural form for multi-story buildings just because of great flexibility. Multi storey steel buildings have wide range of applications such as factories, offices, shopping malls, schools, hospitals, community buildings. The principal structural elements of a typical multi-storey building are the floors, beams, columns and foundations.

There are too many advantages of using steel structure for multi-level buildings.

The speed of construction is faster than other methods and there is minimum need for storage of materials on site due to the high level of pre-fabrication.

Site management costs can be reduced by 20 to 30% which can lead to a 5 to 10% savings in terms of overall building cost. There are some additional attributes such as flexible integration of building& other requirements.

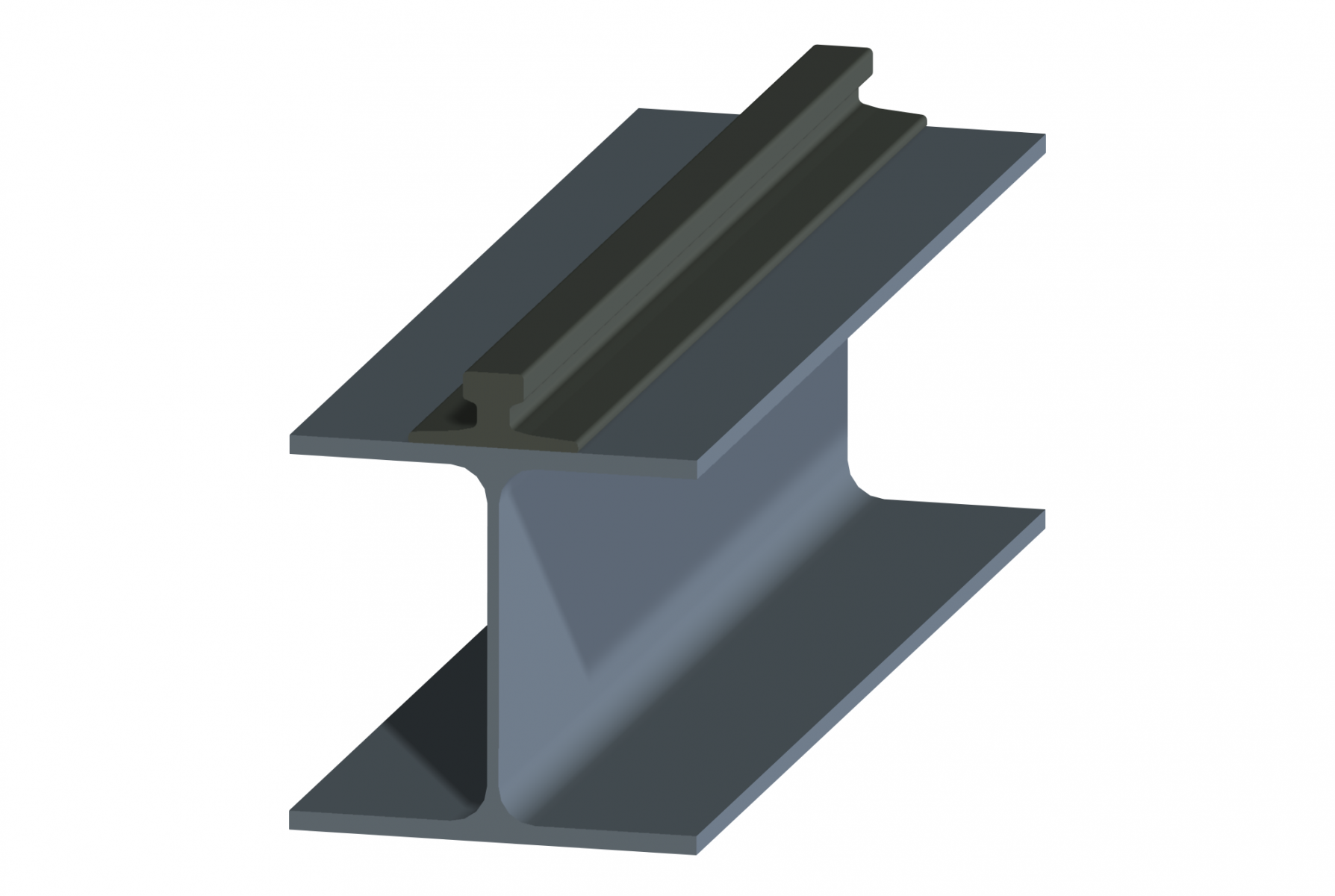

In pre-engineered building primary members is the main load carrying and support members. The main frame members include columns, rafters, floor beams and other supporting members. The section and size of these members vary based on the application and requirements it can be customized. The frame is erected by bolting the end plates of connecting sections together. All the steel sections and welded plate members are designed in accordance with the applicable sections as per the latest Indian codes and standards.

Primary members are,

- Main Frames

- Crane beams

- Floor beams / joists for Mezzanine

- Rafters – Trusses

- Fascia

- Canopy

Secondary structural framing consists purlins, girts, eave struts, wind bracing, flange bracing, base angles, clips and other miscellaneous structural parts.

Purlin & Girts:

- C – Purlins

- Z – Purlins

Purlins and girts are roll formed C & Z sections. Standard size is 200 mm deep with 65 mm flanges shall have a 20 mm stiffening lip formed at 45˚ to the flange. They are bolted on columns, rafters or building walls. They are placed on the roof and perimeter of the building. Hence they serve as a support to the roof sheeting and wall cladding.

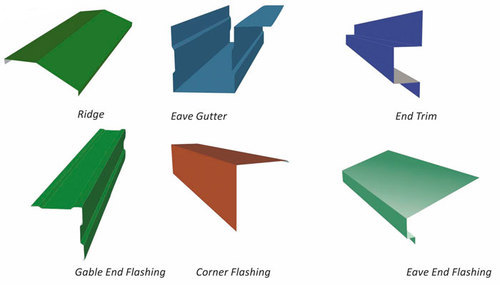

(1) Flashings

Eave gutters, downspouts, curved eaves, wall flashings and trims are manufactured from the same material (base metal, thickness, coating, paint finish and color) as the wall panels of the building.

(2) Doors & Windows

Steel or Aluminum framed doors and windows are fixed to the purlins or the supporting profiled steel either by welding or bolted to the flanges already fixed to the purlins. Proper flashings are applied after installation.

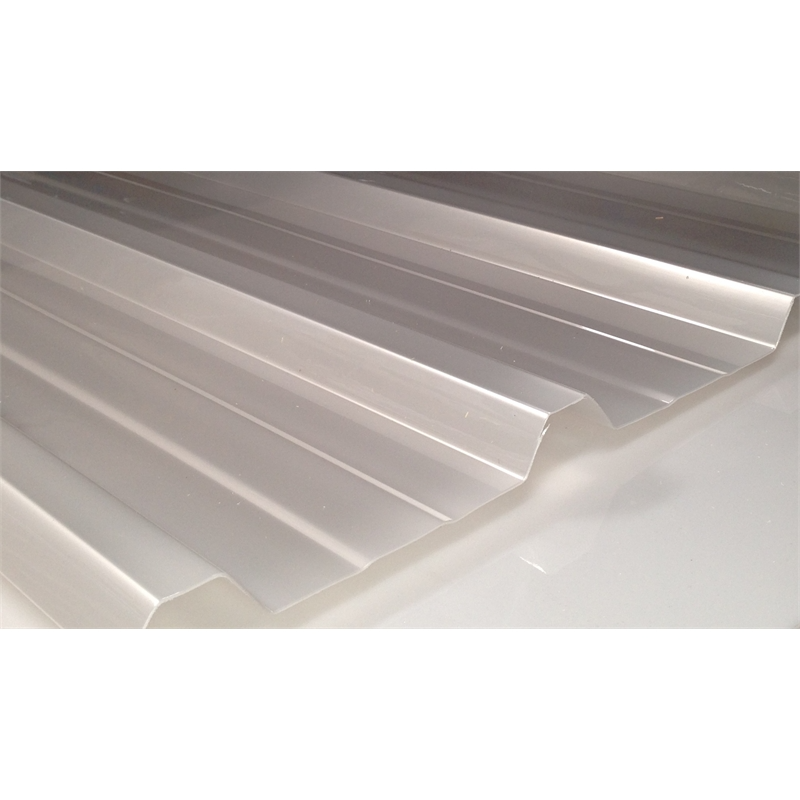

(3) Polycarbonate Sheets , Turbo Ventilators , Louvers

We are providing skylights made from polycarbonate sheets for natural lighting for wall and roof which has standard width of 1000 mm and 365 mm.

We are providing Turbo Ventilators for ventilation in which base made from polycarbonate material for long term leakage proof installation. We are providing louvers for ventilation for some specific uses. These louvers are made from GI & Polycarbonate sheets and it can be fixed on given Roofing Profiles.

Standard mezzanine system consists of profiled steel deck, mezzanine joists, built-up beams and intermediate support columns for various applications.

We are providing mezzanine floor systems by using various floor profiles for multiple applications of mezzanine floors. Mainly for Pharma buildings mezzanines are require as a service and utility area which can be RCC slab or MS cheered plate platforms.

A concrete slab is cast on the steel deck as a semi – finished surface. Steel checkered plates can also be used as top surface.

Components for Mezzanine are,

- DECK SHEETS ( GI / MS )

- PRE-CAST SLAB

- MS CHECKERED PLATE