- Home

- Infrastructure

Shree Vishwakarma boasts of a well-equipped manufacturing unit with sophisticated infrastructure.

In our premises all the products are manufactured under international quality standards.

We have designed our plant for manufacturing of cleanroom panels, doors, clean room equipment, fabrication units, lab furniture and other clean room products. We have customized production line for with CNC machines and experienced and trained workers. We have well known supplier for Raw materials for faster production and easy and faster material arability.

Our in house facility of manufacturing all the products under single roof helpful for clients.Converized Powder Coating plant and chemical cleaning process for puff panels and doors, High pressure puff injection machine , all fabrications tools are available under one roof.

Our Capabilities are,

- FACILITY

- PLANT MACHINERIES

- DESIGN & DEVELOPEMENT

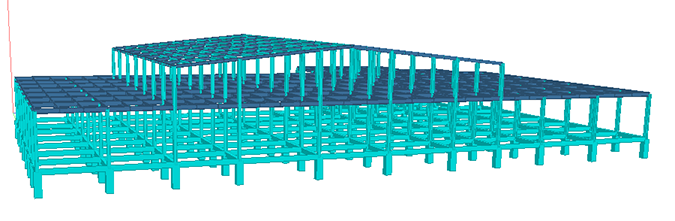

Our manufacturing plant is Located at Dholka, Gujarat. We have one of largest premises for manufacturing of clean room products and steel structure, total area is around 1,50,000 sq feet.

We have two manufacturing units with total build up area is around 90,000 sq ft.

We believe in deliver the best products through these facilities to our customers. We gained enormously with the help of our infrastructure and it has lead where we are standing today.

We are continuously expanding our range of Products in order to face the challenges posed by customers and competitors. We are increasing our plant machineries to reach clients demands related to quality and quantity of products. We are keep investing in machineries and technologies to develop world class production system.

We are one of the leading manufacturers of clean room products among the all competitors. We bought best machines from around the world. CNC machines with latest technology are ensuring that each and every product which produced by us is precise without any errors. All the technicians and workers are used to this machineries and helping us to give best products.

We have,

- Two Manufacturing units

- CNC Cutting machines from Germany

- CNC Bending machine from Germany and Italy

- Manual Shearing Machines

- Cut to Length for Coil Slitting

- High Pressure puff injection machine

- CNC Aluminum profile cutting machine

- Door Buffing Machine

- Spot Welding Machines

- Automatic Converized Powder Coating Plant

- Powder Coating Oven

- Converized Chemical Washing Plant

- Power Presses For Puff Curing

- MIG, SAW Machines

- Radial Drills

- Hydraulic & Electric Press

- All type Power tools, Safety Equipment

Shree Vishwakarma comprises a proficient and committed team to serve its clients the best. The team at our helm is well versed with the techniques and developments of the industry and recognizes its functions well.

We have sufficient members to design and working on clean room projects, specific clean room products, PMS, development, execution, PEB projects with help of experience and developed software.

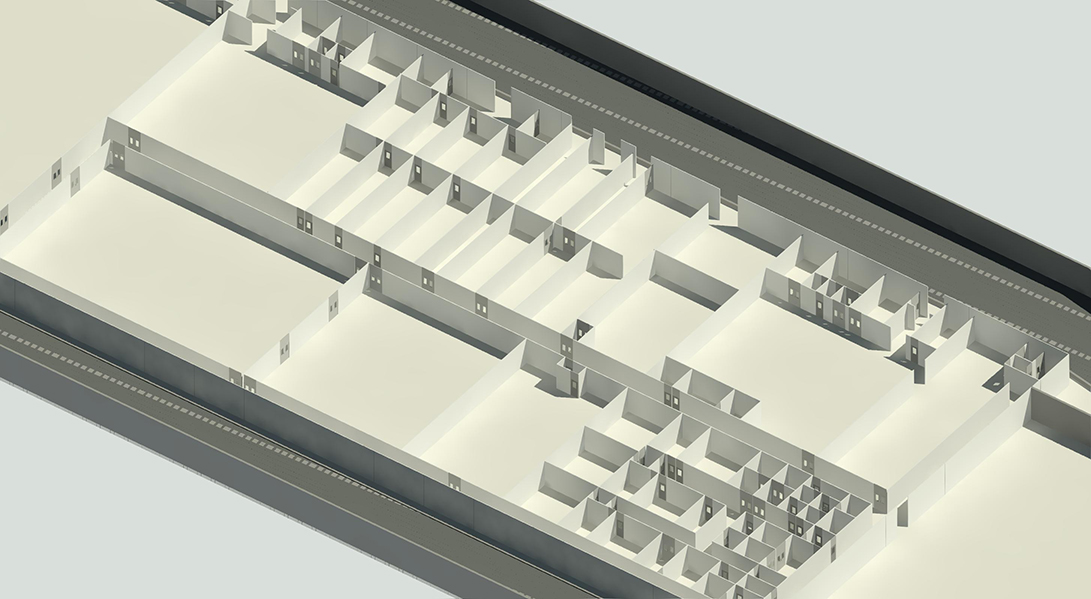

We are capable to visualize in front you what you want to do in your project by using 3D Modeling Software. Due to this we can help customers to take fast decision on the work and process.

We can develop products or modify our standard product as per client’s requirement. Our designing team can customize all the products as per client’s requirements for some specific and critical products and projects.

We are using 3D modeling and analyzing software to visualize actual plant condition before and after installation.